PDF files :

Surge Protector

(480k)

Standard

Straight Modules

Standard Curve Modules

Wide Radius Curve Modules

Transformer Platform

Web page:

You won't find the word defined in Webster's Dictionary. And

if you ask three or four people at a train meet you'll probably get three or

four different replies all trying to define or defend their understanding of the

term Hi-rail. It's not so easy to give a clear definition because the term is

very subjective, each person having his own interpretation of what the term

means. I think the real obstacle in coming up with a generally accepted

definition is that there are those of us who will try to defend or make

apologies for what it is not. There are those who would tell us in no uncertain

terms that we are not O Scale model train hobbyist! The way I see it, strictly

speaking, the technically universally accepted definition of O Scale is that it

represents modeling scaled down from the prototype to a 1/4 inch representing a

prototypical foot.

Beyond that technical measurement, any further definition of

O Scale is a person's personal elaboration. A renown modeler of O Scale, John G.

Macleod, last year wrote in 48/ft. O Scale News, an article entitled, "What

Is An O Scale Railroad?" He maintains that O Scale encompasses a mass of

different identities, including Proto:48, Hi-Rail, Scale-plate, Semi-fine,

Outside 3rd Rail, Center 3rd Rail and all kinds of numerical combinations and

concludes that O Scale is all of these! He goes on to say, "All approaches

are equally valid." Who's to say you can't run an O Scale train on three

rails? After all I've seen three rail prototype track albeit it was laid in that

manner so the railroad could run both standard and narrow gauge trains on the

same rails. What about the New York City subways and interurban trains that use

a third rail for their electrical power. And there are O Scale layouts that use

an outside third rail for their power. One of the oldest and most impressive O

Scale layouts in America using an outside third rail is set up each holiday

season at the Cincinnati Gas and Electric Company.

As the owner and operator of the JL/ATSF RAILWAY and

co-author of the book Realistic Railroading with Toy Trains, I'd like to give

you my interpretation of the term Hi rail. Unlike other model railroaders, Hi-railers have the distinction of coming from a toy train heritage almost 100

years old ‹ Lionel Trains. In fact, we know that Mr. Cowan almost 60 years ago

was thinking about prototype equipment when he produced his first 700E Hudson

locomotive. However, very few references were made that long ago or even more

recently to the term Hi-railer. From my research, the only early use of the term

Hirail that I could find was a somewhat derogatory label used by O scalers.

Tinplate track is about a quarter of an inch higher than scale track and has

three rails thus the term Hi-rail. There are probably other early references but

the antecedent of the term is no longer important. In the 1990's it has become

identified with those train operators that would like to pattern their layouts

and trains on the prototype.

To get to the bottom of its meaning we need to briefly review

some of the confusing definitions usually made by persons that are not Hi-railers. Whether Hi-rail trains are to be called toy, model or miniature

doesn't make much difference. If one were to ask an O gauge hobbyist the

question what is Hi-rail, he might say, "oh a Hi-railer runs big

locomotives on three rail track." Or say, "he's a tinplate Lionel

Train operator who likes to run long trains." If we were to ask a serious

Lionel Train collector who may also occasionally run his trains, he might say,

"Gee I don't know, he's some guy that's pretending his trains are more

realistic than mine and therefore better!" or "Hi-railers are very

serious about their trains and don't have much fun." Which of these

comments holds any truth? Each of these answers probably holds some truth .

Hi-railers are not a superior or snobbish group of hobbyist.

We simply want our trains to appear more realistic or prototypical. We want our

entire layout to appear as realistic as possible. If a Hi-railer wants to run,

let us say, an O Scale Union Pacific turbine with 20 scale UP boxcars, but on a

"traditional" layout, who's to say he can't call himself a Hi-railer?

I'll give you an innocent example of what I did to my Lionel

Trains when I was sixteen years old. In 1952, my brother and I bought our first

Lionel locomotive, a Hudson Lionel 773. Realizing what a good choice we had

made, we also realized that the name "Lionel Lines" on the tender and

773 on the cab were totally fictitious. From the Atchison, Topeka and Santa Fe

Railway System, we obtained a book entitled "Santa Fe Car and Locomotive

Plans for Model Railroaders" published by Kalmbach Publications. Looking

through the book, we found a 4-6-4 that we thought at the time looked pretty

much like our Lionel Hudson, so we proceeded to remove the "Lionel

Lines" and 773 and replaced them with the number 3462 and A.T.&S.F. on

the cab. That was a lot more realistic. I've never had any regrets about

changing the name and number even when many years later I began to realize what

a collector's trophy this locomotive had become. Looking back over forty years I

now realize that I was a pioneer Hi-railer seeking realism for my trains.

Realism takes many levels and each Hi-railer will determine for himself a level

he'd like to attain.

There are several levels in attaining a prototypical layout

and each of us has our own expectation. Webster's defines the word prototype as,

"an original model on which something is patterned" or perhaps another

way of saying patterned on the "real thing." See how this Prototype

Pyramid fits your Hi-rail objectives. The basic step is to operate railroad

equipment as close to 1/4 inch scale as possible. The next step up the pyramid

is "Generic Interest." What will be your mixture of prototype

railroads and types of equipment? Then comes the decision about "Era,"

motive power, rolling stock, buildings, signs, cars trucks, people are carefully

selected to represent a particular time period, past or present. This leads us

up the pyramid again to the "Locale of Railroad," the particular

geographical depiction of a specific area where this railroad operates and

includes the location, topography and season of the year. At the very top of the

pyramid is a choice to operate a "Specific Railroad" along with all of

the other steps of the pyramid. This entails repainting, re-lettering, and

weathering the locomotives and rolling stock. One may also operate rolling stock

that is individually numbered and finally operating the trains in a prototypical

manner. If all of these steps were followed, then for sure we'd all agree that

it's very prototypical and much different from a tinplate toy layout.

Of course there are some given restraints that an O gauge Hi-railer

must contend with namely operating on three rail track. However, except for the

huge couplers and the fact that our O gauge train wheels are designed to best

operate on three rail tubular track there aren't really any other restraints

preventing a Hi-railer from operating an O Scale railroad. Only for the

"dye-in-the-wool" O scale modeler, who gives Hi-railers a

condescending smile and says under his breath, that while we may think we are

operating in O scale its impossible because we are really tinplate toy train

operators. But who needs their acceptance and approval? We need not give them

the time of day! By the way, the word tinplate has nothing to do with our

Hi-rail model trains. The word is an archaic reference to what was and unless

one is using Lionel type tubular track, you won't find any tinplate on a Hi-rail

layout. John Macleod concluded in his article from 48/ft. O Scale News,

"Personalize your layout to suit your priorities. My version of O Scale is

no better or worse than yours or his or hers, what matters is how well your

version suits you."

Because a few manufacturers of model trains decided that

there seemed to be a growing trend in the O gauge Hi-rail market they began to

cater to Hi-rail with more and more prototypical products. And I don't mean only

manufacturers of motive power and rolling stock but of everything we'd like to

see on our layouts. A Hi-railer not only wants to be as close to 1/4 inch scale

as possible for his trains but also his model town, cars, trucks, people all

other details. If he or she does not model these items themselves they can

be carefully selected from the marketplace as close to scale as they can find.

Even, later discarding certain items for more prototypical ones as they become

available. Tony Koester wrote in the revered scale model magazine "Model

Railroader" as it pertains to HO modelers seeking greater realism, that

this trend toward realism has grown to embrace structures and even operating

practices. This applies as well to Hi-railers. Does being a Hi-railer mean that

we no longer want Lionel accessories and buildings? Not necessarily, many of the

Lionel plastic building kits, particular the classic ones like the Grain

Elevator #820K, the Rico Station #825K, the Engine House #835K and the

Passenger/Freight Station #83K, are all nearly perfect scale and with some

customizing, fit perfectly with scale equipment. When it comes to the Lionel

operating accessories, that's a more complex subject. The operating accessories

are toys and the rolling stock that's usually associated with these accessories

are not in any way scale. So maybe this is where we bend the rules of scale. A

customizing job does improve their appearance on our layouts and besides who

doesn't get a kick out of watching an operating Saw Mill or Icing Car in action?

One operating accessory that comes close to the prototype is the Water Tower

#138, which is back again in the Lionel catalog.

A final area in which Lionel Trains has particularly helped

Hi-railers achieve their objective has been with their sound systems. Lionel

aims at producing absolutely prototypical sound for their locomotives. Also

Lionel's power control system with "Train Master" Command Control and

its remote Cab-1 control provides added realism and flexibility for Hi-rail

operators.

Hi-rail operation and layouts are gaining a lot of

"steam". As the Hi-rail manufacturer provides more and more product

for us we are challenged to use their scale equipment in building and operating

more realistic and prototypical layouts.

Joe Lesser

Written for Classic Toy Trains

May, 1997

D.C. Area Independent HiRailers

Module Building Techniques and Notes

Edited by Frank E. Qualls, © DC Area Independent HiRailers, May, 1998

Since I started building modules using the plans of The

Independent HiRailers, I have developed some building techniques and made

some construction notes. I think these techniques and notes are worth sharing

with others who are starting to build their modules.

The first thing I did to improve my modules was upgrading

all of the wire specifications from 16 to 14-gauge wire. The reason for using

the 14-gauge wire is to ensure that there is no locomotive slow down due to

the heavy current requirements of running multiple locomotives, with their

four or more motors operating, as well as lighted passenger cars. Stranded

14-gauge copper wire, which comes in various colors, is available in the

electrical department at Home Depot or other national hardware chain stores.

The Gargraves track we use does not have a common ground

between its two outer rails. On all full-length pieces of Gargraves track used

on the modules solder a stranded 16-gauge jumper wire to the outer

rails between the twelfth and thirteenth track ties. Additional jumper wires

are not required on any other short pieces of track used on the module since

they are connected into a piece of track which has a jumper wire installed.

Using the jumper wire on the Gargraves track helps to facilitate the usage of

common ground wiring on the module and the modular layout.

Proper construction of the bench work for the modules is

very important. Sanding the wood flush on all sides gives a fine finished look

to the module’s bench work. Since a bridge track is not used in this module

design it’s important that the module’s bench work mates tightly together.

The technique used to achieve this is to set the modules up on their legs

prior to laying the track. Then butt the ends of the modules together, secure

them with C-clamps then check for a tight fit between the module decks. If

required, use a belt sander with a #50 or #80 grit belt and sand each

end of the modules to ensure a tight fit. Note: When doing this it is

important to check for the high spots that are preventing a tight fit on each

end and sand them down. A power or manual planer can also be used for

this.

After the bench work is sanded, install the roadbed, then

spray paint the module deck and roadbed flat black. Flat black latex paint,

available from Home Depot, can also be used for painting the module deck. The

purpose for painting is because scenery material and ballast will be lost

during transport of the modules. The black paint prevents bare wood or cork

from showing on the module if this occurs.

After the module deck and roadbed have been painted flat

black, you will start to lay your track. To facilitate the connecting of the

wires to the track, holes are drilled through the deck of the module. Prior to

drilling these holes, cut approximately a 3/8” by 3/8” square hole in the

roadbed beneath each rail where a wire is attached. This makes drilling the

holes through the deck easier. Normally, the power and ground wires are

connected to the tracks between the fourth and fifth track ties. Mainline

tracks one and two will have three holes drilled under their rails and track

three will have only two holes drilled.

Typically, when beginning to lay track on a module, it’s

customary to start with a full 37-inch piece of Gargraves track. There are

some additional track preparations required. Since all wires are soldered

to the track from underneath the module deck, all three rails need tinning

with solder. The center rail requires using a Dremel tool with a grinding

stone attachment or either a hand file to remove the blackening to aid in the

adhesion of the solder to its rail. The pre-tinned power feed wire for each

mainline track is then soldered to the center rail after the blackening is

removed. Please use a wire of sufficient length to reach the barrier strip for

connecting after terminating it with a spade or ring lug.

These modules use common ground wiring. The main ground

wire for the module is soldered to the outside rail of track number one. This

wire connects to the main ground on the module barrier strip. Along with the

power feed on the center rail another ten-inch long ground wire is attached to

the other ground rail on track number one. All three of these wires are then

fed through the holes on top of the deck. The second ground wire on track

number one is then fed up through the hole beneath track number two for

connecting to its ground rail closest to track number one. Track number two’s

other ground rail then receives a ten-inch long ground wire which is fed

through the hole on top and subsequently gets fed up to track number three and

connected to its ground rail. Once all power and ground wires are connected to

their respective rails, align each 37-inch piece of track to be flush with the

edge of the module and spaced as per the specifications. Then pre-drill the

track ties and screw the 37-inch piece of track to the module deck. Note:

This technique of connecting ground wires eliminates trying to connect four

ground wires to one barrier strip ground terminal.

The next step required is to cut a piece of track 12-inches

long. This piece of track fits into the 37-inch piece and completes the

48-inch length of track required for the module. There will be some track

overhanging the end of the module. Secure the 12-inch piece of track to the

module deck with screws. Gently tap the overhanging piece of track to ensure

that the track pins of the 12-inch piece of track are seated tightly. Next,

locate a 2-inch by 2-inch by ½-inch thick or similar flat piece of metal,

which you will use as a gauge and lay it flush against the opposite end of the

module bench work and track. Gently tap the end of the overhanging piece of

track to ensure that the end of the 37-inch piece of track is flush with the

end of the module.

Cut the overhanging piece of track one quarter of an

inch from the end of the module using a Dremel fiberglass cutoff wheel.

The quarter inch of track remaining requires using a hand file to adjust this

track flush with the end of module. Filing allows you to control how much

track material you remove and alleviates the problem of cutting the track too

short. Use straight and even filing strokes and the flat piece of metal as a

gauge. Check often with your flat metal gauge positioned flush against the

module bench work and track to ensure when the track is flush with the end of

the module.

Straight track is critical to smooth operating of the

trains on our modules. When all the modules are connected, the three mainline

rails should be as straight as the rails on a prototype railroad. This is

achievable using a four-foot metal ruler available from Home Depot or other

national hardware chain stores. Using the ruler as a straight edge, position

it in the track groove just below the track railhead on the outer rails. Once

the ruler is in position, loosen the track screws and pull the track into

straight alignment against the ruler. Please make sure that you maintain the

standard 4 ¼-inch spacing between the track’s center rails. After

completion of this procedure, your track should be as straight as an arrow!

After all tracks are secured to the module deck, terminate

each wire with either a spade or ring lug. If you are not using color-coded

wire, then identify each wire with adhesive number markers and then connect

them to their proper terminal on the barrier strip. Please consider using #1

for Track 1, #2 for Track 2, … and #4 for Ground, #5 Accessories, etc. The

next step is to perform continuity checks to ensure that your wiring is

correct. This can easily be done using a volt-ohm meter set for measuring

ohms. Using wire staples tack down any long lengths of track wires to the

bottom of the module deck and use wire tie wraps accordingly. The final step

is to fill in the holes the wires pass through from the bottom of the module

using either RTV or caulking material. The purpose for doing this prevents the

ballast from falling through the holes of the module when it’s applied.

Prior to laying your ballast ensure that the track ties at

each end of the module for each track is flush against the edge. Note: Failure

to do this step will result in a gap between the track rails and the module

deck. This gap can cause the track to become snagged on objects and result in

damage to the rails.

Frank E. Qualls © reserves all rights to this document.

11/98

Top of Page

Module Specifications

DC Area

Independent HiRailers

Module Specifications and Information

To present a uniform but distinguished modular display,

participants are encouraged to build their modules to the following Independent

HiRailers specifications:

Stain the module sides, ends, and legs with Minwax

number 2716 Dark Walnut stain. This product is available from Home Depot

in small cans and is easily applied with an old rag or paintbrush.

Paint the cork roadbed before adding track ballast. With

the constant transporting of modules, you will lose some of the track ballast.

Then the unpainted brown cork roadbed becomes visible. Independent

HiRailers who use a 50-50-ballast mix have painted the cork roadbed on their

modules black. I have done the same and find this color blends very well and

its not noticeable when some track ballast is lost.

Paint the inside and outside of both Gargraves track outer

rails with Floquil number 110070 Roof Brown paint. This paint

color is the closest that resembles the color of rust on the rails. Before

painting your rails wipe the grooved side of the rail below the railhead with

an alcohol soaked Q-tip to remove the oil residue. A number 4 artist’s

paintbrush easily fits in the groove and helps make painting the rails easy.

Ballast the track with a 50-50 mix of Woodland Scenics Coarse

Gray number B89 and Coarse Cinders number B90. For

instance on my modules for ballast I chose to use O Scale Limestone and

Coal Ballast in a 50-50 mix which I purchased from Jeff Green at

Kelster Interprises, 12463 Atwood Pl., Fishers IN. 46038, 317-595-0831. This

product is also available in Dark Gray and costs as follows: 1-25

pounds at $1.25 per pound plus shipping and 26 pounds or more

the cost is $1.00 per pound plus shipping. If you decide to use O Scale

ballast call Jeff Green and give him the total track footage you are going to

ballast and he will calculate how much O Scale ballast you need. Note: I

find this product is very cost effective. Woodland Scenics costs $2.75 for an

eight-ounce bag!

Scenery on your modules is a personal choice to which the

Independent HiRailers encourage use of your imagination, but remain within the

High Rail and O Scale theme of model railroading.

These are current Independent HiRailers specifications to

keep in mind when constructing your modules.

For more information contact Frank E. Qualls

at fequalls@aol.com

Top of Page

Replacement Power Connectors

For

Independent HiRailers Modules

Specified

and compiled by Frank E. Qualls, DC Area Independent HiRailers, October, 2002.

All of the current Independent HiRailers Module

drawings show a Radio Shack, Molex type connector. Molex, the OEM manufacturer

of our connectors decided to stop producing them in 1995. Now all of the bulk supply of those connectors at Radio Shack

Unlimited has been exhausted. Please find below a new replacement connector

that has been specified and is readily available to all who use the

Independent HiRailers module drawings.

The

replacement connector I have selected has the same six-pin configuration as

our original Molex connector. It also is a Molex type connector rated at

nine-amperes per circuit. I have

successfully used these connectors on my multiple 8-module set train yard.

The yard track’s wiring harness uses these type connectors on the

modules interconnecting pigtails. The

DC Area Independent HiRailers has since started using these connectors on our

mainline harnesses on all new modules built which have dioramas consisting of

two or more modules. We continue

to use the original Molex connectors on the ends of these modules to mate to

all other modules with the same original connectors.

We have been doing this successfully for the last five years without

any overloads, discoloration or melting the Molex plastic connector shell

rated at nine-amperes. We also use this same connector for any other

application on multiple module sets that require multiple wiring harnesses.

Therefore, after consultation with other Independent HiRailers module

group coordinators I am specifying the below Independent HiRailers “Replacement

Connector.”

The below

listed parts are marketed and sold as Molex/Waldom Power Connectors.

These connectors are Molex OEM .093” Diameter Connectors with a

per circuit current rating of 9 amperes. They are available at Radio Shack

and many other electronics parts dealers.

Listed below are the Radio Shack part numbers and four mail order

electronics suppliers who have a good track record of stocking these parts and

whose prices are competitive. Please

contact each of the below listed electronics suppliers and request their

latest parts catalogue.

Digi-Key Corporation

701 Brooks Ave. South

Thief River Falls, MN 56701-0677

1-800-344-4539

Name Molex OEM P/N

Digi-Key #

Price

Plug/Male

03-09-2061

WM1317-ND

1 @ .62, 10 @5.09

Receptacle/Female

03-09-1061

WM1316-ND

Same as above.

Male Pin

02-09-2103

WM1100-ND

10 @ .74, 100 @ 5.94

Female Pin

02-09-1104

WM1101-ND

Same as above.

The

above parts are also available from:

Mouser Electronics

Newark Electronics Allied

Electronics

www.mouser.com

www.newark.com

www.alliedelec.com

800-346-6873

800-463-9275

800-433-5700

Radio Shack

Name

RS Part #

Price

Plug/Male

274-226

1.39

Receptacle/Female

274-236

1.39

Note: The Radio Shack parts were shown in their

2000 catalogue but they may also be discontinued.

So please use the information above from the other electronic

suppliers. The best source for

these parts is Digi-Key.

Top of Page

HiRail Ballast Technique

By

Frank E. Qualls

When displaying my HiRail train modules in public I have

received many compliments on the track ballast. My mentor, Steve Horvath,

founder of the Independent HiRailers taught me the ballast laying technique I

will detail below.

To begin your track ballast project you want to use a high

quality ballast such as Woodland Scenics, Coarse Gray # B89 and Coarse Cinders

# B90. I chose to use O Scale Limestone and Coal Ballast from Kelster

Interprises. (Further information on Kelster is listed in the Independent

HiRailers Module Specifications.) Either of these ballast products will work

just fine. The Independent HiRailers ballast specifications call for a 50-50

mix of gray and cinders.

There are many devices one can use for laying ballast.

Normally, I utilize a small plastic cup as a ballast dispenser. I squeeze the

top of the cup to form a U-shape to control the flow of the ballast. It is

spread onto the track ties between the rails two thirds of the length of the

track. Next, spread the ballast the full length of the outside of the track

covering the tie ends and tapered roadbed. Using your index and second finger,

start in the middle of the track spreading the ballast on each side of the

center rail by pushing it along the full length of the track. As you do this,

some of the ballast will fall outside of the track on top of the ballast

already on the tie ends. As the ballast continues being pushed along by your

fingers, the spaces between the ties are filled. The excess ballast continues

moving along the tops of the ties filling in between the ties where no ballast

was initially spread. Repeat this procedure until the entire track where

ballast is laid has been spread to the opposite end. Using this technique you

should get to the end of the track with excess ballast or having to add a

little to finish the job.

Any ballast remaining on top of the ties can be gently

brushed between them with a small ¼” artists paintbrush. The outside

of the track requires using the paintbrush to remove the ballast from the top

of the ties. As you brush the ballast away ensure that it is level between the

ties and at the ends of the ties. Taper the ballast away from the ties and

slope it to the contour of the roadbed to create a swell between the tracks.

(Note: More ballast may be required for tapering and to aid in the making of

the swell.) Once you have completed this on each side of the track, you are

ready to move on to the next track. Upon completing all three mainlines and

any siding tracks, you are ready to secure the ballast.

Materials for this project. Floquil Roof Brown Paint, Ballast, Glue water

mixture, Glue, Wet water sprayer and track.

Applying the track ballast.

The two finger ballast spreading technique.

Brushing ballast off of the ties.

Creating a swell between the tracks.

Photos by Randolph Co.

Top of Page

Securing Your Ballast

By

Frank E. Qualls

Before gluing your ballast, it is very important that the

ballast is level between the ties and outside the rails and at the tie ends.

This ensures that cohesive bonding occurs between the ballast particles and

all sides of the track ties. It also prevents the flaking off of the ballast

after the glue cures.

Prepare a spray bottle capable of mist spraying a solution

consisting of water and a few drops of liquid dish detergent. This solution is

called “Wet Water”.

Using the “Wet Water” solution spray the ballast

well prior to applying the glue mixture to prevent ballast “Washout”.

Mix up a strong 50-50 White Glue and warm water mixture

with a few drops of liquid dish detergent in a squeeze bottle with a spout.

Shake this solution vigorously for it to blend well so that it flows smooth

and freely. This solution should not be thick and stringy.

Begin gently drenching the ballast between the ties on each

side of the center rail moving backward and forward over a 9 to 12-inch area. (Note:

Do this gently. Do not splash the glue mixture onto the ballast. This will

only serve to dislodge it. Take your time until you get a feel for how the

glue mixture is flowing onto the ballast.) You should see the white glue

mixture leaching into the ballast at the tie ends outside the rails. When this

is visible, begin to soak the mixture on top of the tie ends on both sides of

the track.

After you see the mixture leaching into the tapered ballast

on the roadbed, begin to soak that area until you see the white glue mixture

rise to the top of the ballast. Once you see the white glue mixture run onto

bare plywood outside track one or track three or rise to the top of the swell,

you know that enough glue has been applied. When this occurs continue to move

further down the track repeating the above steps. Be sure to continue to use

the “Wet Water” mist generously as you move along the length of the

track prior to applying the glue mixture.

Repeat the above procedures for the ballast on each track.

36-hours after the glue cures the ballast should be rock

hard and there will not be any flaking of the tie ends, tapered roadbed or the

swell between the tracks. This technique has been used successfully on the

twenty-three modules that I own. Have fun as you ballast your track using

these techniques on your modular or permanent layout.

Wet water application.

50-50 Water and Glue application.

Cleaning track before painting.

Floquil Roof Brown paint application to track.

Completed job on the tracks.

Photos by Randolph Co.

Top of Page

Slowdown Circuit

Upon seeing the “Slowdown Circuit” drawing on the HiRail

egroups list posted by Matt Jackson of the Angels Gate HiRailers. I (Frank E.

Qualls) contacted Matt to inquire about posting his circuit and edited text on

this site. After Matt agreed to the editing I had done to his text, the

HiRailers Unlimited is now pleased to present this circuit drawing and

accompanying instructional text for all HiRailers.

Constant 1.5 volt Headlight

DC Can Motor Slowdown Circuit for 3-Rail

By

Matt Jackson

Angels Gate HiRailers

The following circuit I will describe below is based on a

minimum rating four-ampere bridge rectifier modified for reducing the voltage

applied to DC Can motors in three-rail trains.

A bridge rectifier is an electronic device, which has four

electrical terminals and four regular diodes arranged as depicted in the

drawing below. Each of it’s terminals is individually identified as either

Plus or (+), Minus or (-), and two labeled as AC or (~). To accomplish what I

am proposing as a “Slowdown Circuit” will require electrically tying the

Plus and Minus terminals of the bridge rectifier together with a jumper wire.

What this basically does is electrically rearrange the diodes into two pairs

for bi-directional DC current flow (+/-) and results in a 1.4 volt reduction

at the output.

Think of a diode as a switch that turns on at .7-volts. The

first diode in the pair does not switch on (or conduct) until the .7-volt

threshold is reached, but the second diode in series is still “off.” An

additional .7-volts is required to switch on the second diode in series for a

total of 1.4-volts before current flows through both of them. Then the

required switching voltage reduces the output. For further voltage reduction

you could install a second modified bridge rectifier for a drop of 2.8-volts.

One bridge rectifier is required for each motor.

With a constant voltage lighting setup, the 1.5 to 3-volt

bulb tied across the leads in parallel with the diodes will light when voltage

is applied to the circuit. The lamp will always see the voltage dropped across

the diodes whether it is positive or negative voltage because of the

bi-directional current flowing through the bridge rectifier. In this circuit

the voltage drop will always be at 1.4-volts.

One modified bridge rectifier rated at four amperes or

more is required for each motor. It is connected in series with the

DC output from the reverse board. To determine which wire to use trace the

wires on your DC can motor back and one of them should return to the reverse

board from each motor. (Typically these wires will be the same color). Remove

this wire from the motor terminal and connect it to one of the bridge

rectifier terminals labeled “AC or (~).” And then connect another wire of

sufficient length to the motor to reach the other rectifier terminal labeled

“AC or (~),” this completes the circuit. Do this for both DC can motors.

Also physically attach the bridge rectifier to the locomotive chassis with a

small screw and nut for heat sinking. Carefully check over your work to ensure

that there are no bare wires touching the motor frame near its terminals or

the locomotive chassis. This completes the installation of your “Constant

1.5-volt Headlight/DC Can Motor Slowdown Circuit for 3-Rail.”

Top of Page

Setting the Stage

By

Frank E. Qualls

Some of you know that I have worked in the electronics

industry as an electronic technician for over twenty years. My career

specialty is in radio frequency and microwave theory as used in satellite

communications. Over the last five years I have enjoyed a close friendship

with Otto Schade, Jr., a fellow HiRailer and model train hobbyist. Otto is a

retired electrical engineer who enjoyed a long and distinguished career with

RCA in semiconductor device and circuit technology. Last year (1998) after I

read about the problem of transient voltage spikes occurring in model train

transformers and the damaging effect they have on train electronics I began to

think about a solution to the problem. I talked with Otto, and discussed my

ideas for a simple solution that could be shared with all HiRail modelers who

choose to use it. We collaborated and what follows is our simple solution to

transient voltage spikes, which a hobbyist can build.

Simple HiRail Surge Suppression Circuitry

By

Otto Schade, Jr.

April 15, 1999

Background

On September 30, 1998 QSI (Fred Severson and Jim

Christensen) published a technical report which described voltage-spike

testing they had performed at QSI in response to an increasing number of

electronic reverse-unit field failures. A result of this concern was a “PowerGuard”

surge-suppression product and the statement that QSI sound systems could be

operated safely with Lionel’s ZW and other traditional transformers. The MTH

Z-4000 MUST use PowerGuard

protection

in order for the QSI warranty to be in effect but use of a Z-750 - as well as

other untested electronic power supplies - VOIDS any warranty. In a January,

1999 addendum, QSI formally stated that further tests showed ALL transformers

to be suspect. Unless PowerGuard is used, they will not warranty any products

against damage caused by excessive voltage or voltage spikes. The

surge-protection circuitry to be described has NOT specifically been tested by

QSI, but it does closely adhere to their original T.R.E.O.S. (Three Rail

Electrical Operating Specifications) 35-volt spec and later 37-volt “practical”

limit. It is presumed that these values have been derived from the 35V “working”

40V “absolute max” manufacturers’ capacitor specs. The use of a Lionel

(DC) whistle/horn button at full throttle may put up to 26Vrms - i.e., 36.8V

peak (minus a 1.5V bridge-rectifier drop) - on a sound-system power supply

bus. There is virtually no design latitude in a practical protection circuit

during such operation.

Transient Voltage Suppressors

The Microsemi 1500-watt series of bi-directional Zeners

contains nominal 33- and 36-volt devices. The breakdown-voltage tolerance on

the latter part makes it unsuitable for the above spec constraints, narrowing

the choice to a MSC 1.5KE33CA device for the proposed application. Its rated

peak current of 33 amps (for millisecond-order durations) appears more than

adequate, but the 28.2V 5uA “standoff” spec and 31.4 - 34.7 breakdown

range must be considered. In addition, a series of heavy-current spikes - such

as could be encountered in a high-speed derailment - further increases the

34.7V value due to the Zeners’ bulk resistance and positive

voltage/temperature coefficient. The following circuit takes this into

account.

Protective Device Tests

To examine the ruggedness of the 1.5KE-series Zener,

several were subjected to both single high-current 1000uF capacitor discharges

and a 120-hertz 1A/3mS pulse string for about 1-2 seconds. The former produced

about 2-to 20 amp pulses in the order of 10 to 1mS, and the latter about a

10-watt dissipation for the 1-2 second period. No heat sink was used. The

capacitor discharges, simulating the 50-60 volt spikes such as displayed in

the QSI report, produced no detectable Zener characteristics change. The

repetitive pulse string heated the Zener package, but it could still be

touched. A rough estimate puts the breakdown-voltage increase due to bulk

resistance at 1 volt and the temperature-rise component at 3 volts, for a

total of about 4 volts increase caused by the pulse train. This increased

clamp voltage on the track appears reduced by about 1.5V on a sound-system

supply bus, due to the commonly employed bridge rectifier. The resulting Zener

voltage-range spread appears to the electronics as 33.9 to 37.2V.

The MEASURED performance of a NOMINAL 1.5KE33 was 31.5V

referred to the supply bus at mA-level (33V) breakdown and 35.5V with the

120-hertz 1-amp pulse string. Such a nominal Zener permits a 23Vrms maximum

sinewave transformer output. In an attempt to increase the value to allow for

boost-winding voltage at full throttle, 2 diode-voltage drops (4 diodes total

for an AC waveform) can be added in series with the 1.5KE33, raising the

nominal breakdown to 34.5V-permitting a 24.4Vrms transformer output. We still

haven’t reached the 26Vrms level, and the electronic supply bus is raised to

37V in the pulse environment; essentially the “practical” maximum referred

to by QSI. Theoretically, the rule remains: “Don’t blow a ZW whistle at

full throttle”. We will, however, use this augmented 1.5KE33-plus-diode

suppressor in a circuit, which provides an LED clamp indicator.

A Sanity Check

The above study shows that simple inexpensive spike

protection can be provided for the voltage-spec levels quoted in QSI’s

T.R.E.O.S. and subsequent report (s). Unfortunately, spec calculations show

that the traditional Lionel transformer with boost winding should be operated

with some discretion to meet those specs, even with selected protection

components. The 1.5KE-series suppressor shown in the following circuit

schematics is applied to the transformer outputs, but testing suggests it

could also be directly installed on train-electronics packages by the

manufacturer. Doing so would assure supply-bus spike suppression despite

intermittent train/track contact or the characteristics of an “unknown”

train transformer. With regard to transformer application, if train

controllers are often pushed to their maximum output, the more-complicated LED

suppressor circuit should be considered. This situation is the design result

of choosing a clamp level that protects expensive train electronics, rather

than the $1.00 transient suppressor. Of course, if you wipe out a protection

device and don’t know it, the electronics may be on thin ice.

Transient suppression protection is just that-the

neutralization of spikes/surges OUTSIDE a systems normal operating mode. The

thermal packaging of these devices is not intended for continuous peak

clamping of an otherwise normal throttle output-with or without heat sink.

More expensive circuitry having a power transistor and heat sink could

routinely perform such function, but to a throttle designer, it is quite

inconsistent to generate an output which becomes purposely thrown away. Modern

throttle designs and locomotive electronics do not require a boost winding

such as used by the ZW for reliable DC generation and detection. Their modest

(if any) peak-signal increase can permit the continued use of “35-volt”

electronic components in conjunction with spike protection at full 20V

throttle.

The 1.5KE33 transient suppressor has been selected without

knowledge of QSI’s design approach or constraints; or how effective

PowerGuard is. It is an independent response to QSI’s concerns and policy,

has not been endorsed by them, and the reader is left to his own judgement

regarding its use.

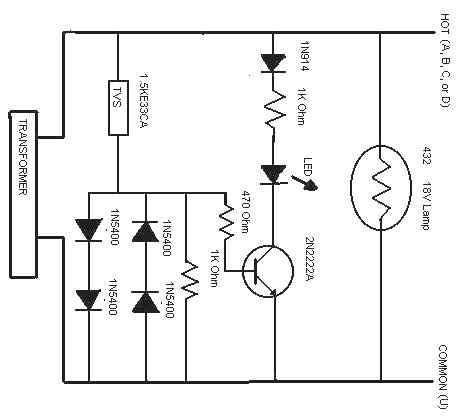

Transient Suppressor Circuits:

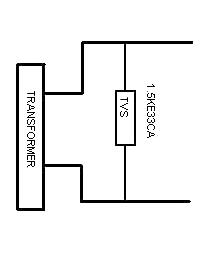

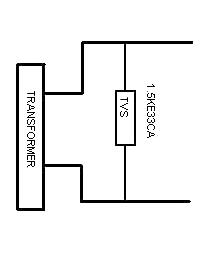

The simplest application of the 1.5KE33 connects it

directly across the transformer/throttle output going to the track between “hot”

and ground”:

As shown, a maximum sine wave transformer out of 22Vrms can

be applied. The whistle/horn button of many traditional Lionel transformers

having compensating windings should NOT be used at full throttle, because

exceeding this value will result in Zener output clamping and possible loss of

protection.

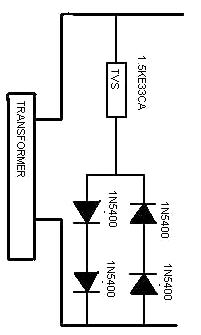

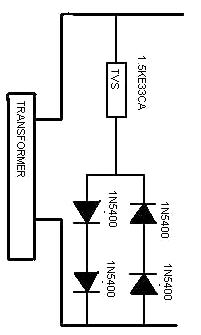

The additional 3A series diodes increases the maximum

sinewave transformer output to 23Vrms:

This is still not enough for full-throttle boost insertion,

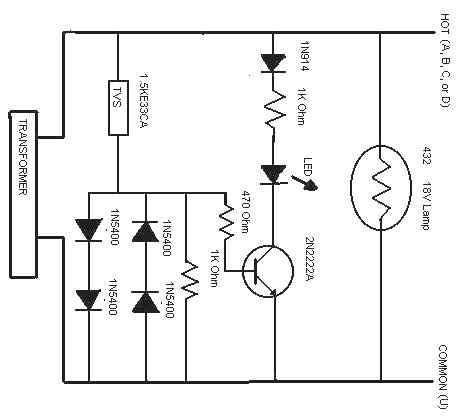

but is the basis for an LED clamp indicator:

The resistors have a ½-watt rating; the LED, diodes and

NPN transistor are available from Radio Shack. When a milliampere-level

current flows through the Zener network, the 2N2222A switch turns on and the

LED is lit in a half-wave mode. At such current levels, there is insignificant

Zener heating and the change of LED state indicates the initiation of a clamp

mode at safe levels. If in addition the upper track feeder is connected to the

center rail, a positive-DC whistle/horn signal convention is sensed by this

LED state change, establishing the maximum permissible throttle setting

allowed on the Lionel transformer. Given a sufficient throttle output voltage,

the procedure tests that a clamp function will occur; at least for low “spike”

voltages.

Build A Simple Surge Suppressor

By

Frank E. Qualls

April, 99

The technical report you just read details what is

described as a simple transient voltage Surge Suppressor. This is not a

detailed step by step “How To” set of instructions for building this

device. The information provided here will give the Hi-Rail hobbyist basic

ideas for layout, packaging and parts sources which he can use. Surge

protection can be had by simply using a single 33-volt Bi-directional

transient voltage suppressor in parallel with each transformer throttle as

shown in drawing number 1. The circuit shown in drawing number 2 with the four

added diodes is recommended because it uses the voltage suppressor breakdown

range to its greatest advantage. Two independent 18-volt load lamps with a

common ground can be added in parallel with each TVS for zeroing out the LED

meters on the Z-4000. Each of these lamps also serve as track power indicators

by illuminating due to transformer voltage and as short circuit indicators by

dimming or extinguishing when a short is present on its respective track. They

are shown in the following pictorial drawings, which depict the number 3

circuit’s project box Top Cover and Perforated Board layouts.

My layout tests have shown that when using the MTH Z-4000

it can be operated at full throttle without illuminating the LED clamp

indicator. However, the Lionel ZW illuminates the clamp indicator at 18-volt

throttle level when using the whistle/horn controller.

Parts List

Below are the part numbers and sources of the parts used to build a Surge

Suppressor.

1 Project Box, Hosfelt part number JAL-3, 4 1/8” x 2 ¾” x 1 9/16”.

1 Black Banana Plug with setscrew, Hosfelt part number BU-00245-0.

2 Red Banana Plugs with setscrew, Hosfelt part number BU-00245-2.

The other parts required for this project are determined

by which circuit you choose to build.

Please refer to the circuit drawings

for the other component part numbers, which are listed in each drawing. The

quantity of parts required would be doubled for transformers with dual

throttles, which require two common grounded independent circuits. Hosfelt

Electronics is a good economical source for all of the above parts and those

in the diagrams except for the Transient Voltage Suppressor.

Please call Hosfelt at 1-800-524-6464 to request a Catalog.

Some of the parts for this project are also available from Radio Shack.

Microsemi Bi-directional Transient Voltage Suppressor rated

at 33v at 1500 watts P/N 1.5KE33CAMSCT-ND. Available from Digi-Key

Electronics call 1-800-344-4539 to request a catalog. Quantity (2) Note: A

Digi-Key minimum order of $25.00 is required. Also available from Mouser

Electronics as General Semiconductor P/N 625-1.5KE33CA. Call Mouser at

1-800-346-6873 to request a catalog. Mouser requires no minimum order.

Micro miniature Pre-punched Perforated Board. Radio Shack P/N 276-1396

Miniature Lamp Screw Base. Radio Shack P/N 272-356. Quantity (2)

2 Number 432 Lamps 18volts @ 250 ma. 1 Red, 1 Green or 1 Amber Lamp.

Available from Local Hobby shops.

One 4 position barrier strip.

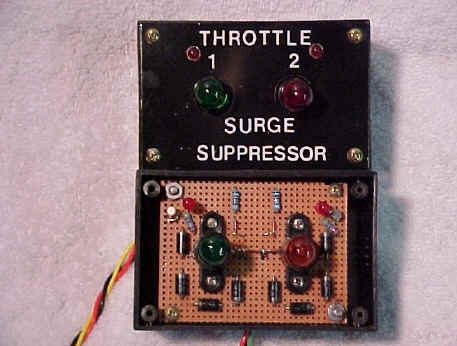

Top Cover Layout

and

Perforated Board Layout

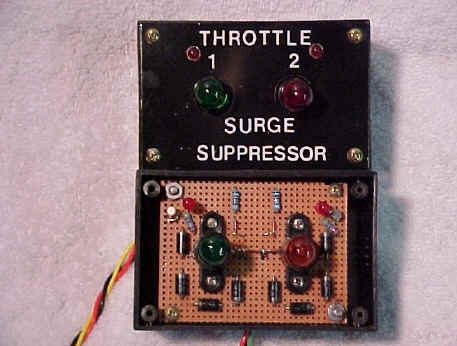

The above photo shows the Surge Suppressor top cover and

Perforated Board Layouts. The 1.5KE33CA TVS and barrier terminal strip for

connecting the Surge Suppressor to the transformer is underneath the

perforated board.

Simple Surge Suppression Protection

By

Frank E. Qualls

This photo shows the Simplest form of Surge

Suppressor protection one can have economically. The dual banana plug on the

left depicts the 1.5KE33CA TVS diode and a bayonet type lamp holder with

1.5-inches of wire and a number 1445 lamp attached. The banana plug is plugged

into both the plus or red and ground or black binding posts terminal outputs for

each throttle on the Z-4000. The number 1445 lamp provides a load for zeroing

out the Z-4000 voltage and ampere meters. The Radio Shack part numbers for the

dual banana plug shown is 274-717 and the bayonet type lamp holder shown is

272-355.

Editors Note: The circuits described have not been

approved or sanctioned by QSI as being acceptable protection for their

products. They have been designed with regard for the QSI T.R.E.O.S. published

specifications and technical reports. I think enough of our testing of the

Transient Voltage Suppressors and feel that this approach is sound to consider

as protection against voltage spikes for train electronics to have chosen it.

QSI, and PowerGuard are trademarks of QSI, Inc. Lionel ZW

is a trademark of Lionel L.L.C. MTH, Z-4000 and Z-750 are trademarks of Mike’s

Train House, Inc. All other trademarks are the property of their respective

owners.

Top of Page

What is Hugo's universal frog ? I want to run

both HiRail (3-rail) and 0-scale (2-rail) cars on my layout, so I had to make

some modifications to the 3-rail-turnouts ! One possibility is shown in the

picture.

On a ATLAS O turnout ( 072) I have made a small slot in the

bottom of the frog parallel with the ties, then I made a small steel triangle

with a hole in the middle. The top-surface of the triangle matches the top of

the rails in the frog. A THROW BAR, between the ties, is connected to the

triangle by a rivet through the slot in the frog bottom. Now by moving this

THROW BAR the triangle will move from one side to the other and guide the wheel

on the right side of the FROG POINT. The wheel will be supported all the time,

so there will be no derailment and no rough riding through the turnout ! Note

that the GUARD RAILS are no longer necessary and I keep them only because the

turnout looks better with them !

Remarks:

1) If you want to run 2-rail Locomotives through this turnout,

you must cut the connection between the two running rails ( inside the 9th tie

from the front, or you will have a short between the running rails ! ( I just

drilled a small hole, from below, in the tie under the SWITCH RAIL and checked

that the connection was cut ! ) Then you must wire the turnout, as if it was a

2-rail turnout ! No HiRail cars with uninsulated wheels at the same time !!!!!

2) The 2-rail wheel sets has a bigger distance between the

wheels (flanges) - the so called "BACK to BACK of FLANGES" - measure (

NMRA S-4 Wheel Standard "B" = 1.118" (28.4 mm)), this means that

the GUARD RAILS in a 3-rail-turnout ( for smaller back to back measure ) will

not guide the wheel flange on the right side of the FROG POINT and the car might

derail !

3) I only use a solid center rail where the track can not be

seen, otherwise I use my STUD-RAIL-SYSTEM with studs hidden in the ballast

between the ties and pick-up skies clipped on the rollers ! ( See Fred M. Dole's

Story and Photos page 98 to 101 in the December 1998 ( Run 162 ) issue of O

GAUGE RAILROADING ) This STUD SYSTEM gives me the best looking track possible

for the reliable and easy 3-rail-system ! ( THE SAME REASON WHY MARKLIN, THE WORLDS

BIGGEST TRAIN MANUFACTURER, USED IT FOR THEIR HO-TRAINS FOR ALMOST 50 YEARS

!!!!!!!!!)

4) I have tried other solutions "TONGUE SWITCH" in

the frog, "MOVING WING RAILS" etc., but I find the TRIANGLE to be the

easiest and most reliable type of UNIVERSAL FROG !

IF YOU WANT MORE INFORMATION - ASK IN OUR FORUM !

Regards, HUGO B. PALLESEN, TCA 67-1844

Top of Page

Radio Shack Unlimited

401 N.E. 38Th. St.

Fort Worth, Texas 76106

1 (800) 241-8742

Compiled by Frank

E. Qualls, DC Area Independent Hi-Railers, April, 1998 (Updated 1/01)

The current Radio Shack male/plug part number 274-152 and

female/receptacle part number 274-155 specified on all Independent Hi-Railers module drawings are no longer available from your local Radio Shack.

These parts were discontinued by the original equipment manufacturer

Molex about three years ago (1995).

Tandy Corporation headquartered in Fort Worth, Texas and the parent company to

Radio Shack had an industrial parts division known as Tandy Electronics. This

division sold electronic parts to vendors packaged in larger quantities than

normally available from the local Radio Shack.

Since Tandy Electronics is no longer in business their remaining

inventories of the connectors we use are now available in Fort Worth, Texas,

through their warehouse named Radio Shack

Unlimited. They are packed into individual packages, which

contain 5 connectors. The part numbers listed below are for the plug and

receptacle. These connectors are not

packaged with the male and female

terminal pins. These .125”

Diameter terminal pins have to be ordered separately using the part numbers

listed below. They are packed into

individual packages, which contain 25

terminal pins.

Please keep in mind that each connector has six

circuits and they are sold in packages of five connectors, which

require 30 male or female terminal pins.

Please be sure to calculate the correct number of terminal pins you will

need when placing your order.

Radio Shack Unlimited

Name

Plug/Male 11315785

1 pack of 5

@ $2.39

Receptacle/Female

11315793

1 pack of 5

@ $2.39

.125” Male Terminal Pin 11315827

1 pack of 25 @ $4.89

.125” Female Terminal Pin 11315835

1 pack of 25 @ $5.29

These

parts are only available through mail order purchasing. They can be ordered using a credit card at the following

telephone number: 1

(800) 241-8742. The current inventory

that Radio Shack Unlimited has of these connectors

is not known. Therefore, it would

be prudent for those who need them to place your connector orders as soon as

possible. Note: These connectors are still available as of 1/2001.

Top of Page